PrīmX Technology

Founded in 1997, Primekss is the world’s leading concrete technology company, creators of unique, patented steel fiber reinforced self-stressing concrete (SFRSSC) technology – PrīmX.

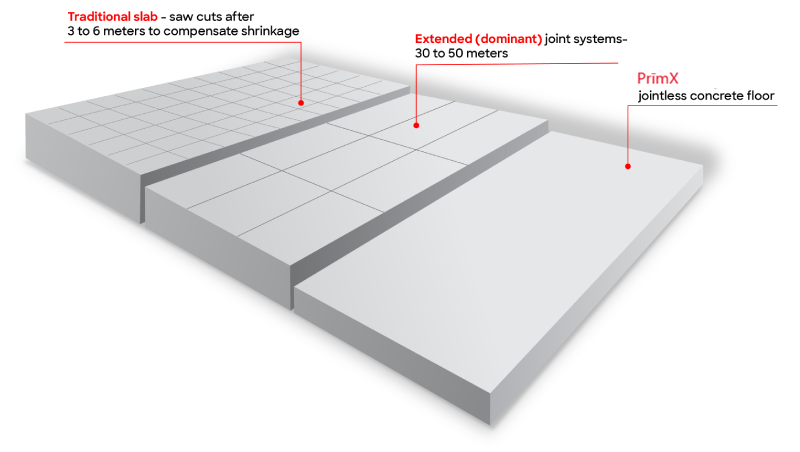

The technology is applied to construct lifetime-flat, dimensionally stable, jointless concrete floors and structural elements. The company has its own Concrete R&D (Research and Development) center that ensures capacity for technology development, and a structural-engineering department to deliver design-built, full-warranty product.

PrīmX – patented steel fiber reinforced, self-stressing concrete (SFRSSC) technology for future-proof construction

-

True flexibility

Jointless floor design allows for total flexibility in racking and other load placement, and also ensures flexible replacement in the future.

-

Robotics and automation ready

Jointless, saw-cut-free, and dimensionally stable concrete floor with minimum maintenance that ensures smooth, uninterrupted operations for AGV and dimensional stability for heavy automation systems.

-

Reduced CO2 emissions

The PrīmX system makes it possible to reduce CO2 emissions by up to 70% due to reduced slab cross-section (consuming less cement and steel) and optimized mix design (better materials).

Our Customers

Your Choice for Gigafactories

PrīmX Concrete Technology delivers design-build, future-flexible solutions for industrial flooring and structural.

- Reputation & Responsibility

Benefit from our full-service design-build project partnerships, guided by meticulous planning and superior quality supported by 5D modeling. - Global Success

With over 27 years of experience and 21,600,000 m²+ of concrete poured across four continents, including two successful giga factory projects in Sweden. - Quality Control

Utilize our proprietary app for real-time monitoring of floors worldwide, ensuring the highest quality standards are consistently maintained. - Sensor SmartX Concrete

Our sensor-equipped slabs provide real-time monitoring of critical floor parameters. - Lifetime-flat, Dimensionally Stable Floors

Minimize maintenance and maximize operational efficiency for the optimal placement of precision equipment. - Clean and Dry Rooms

Our jointless concrete technology prevents dust escape and eliminates dirt accumulation, providing seamless, crack-free surfaces essential for clean and dry rooms. - CO2 Reduction

With eco-efficient practices, materials, and expertise PrīmX reduces CO2 emissions up to 70%. - Future-Flexibility

Unparalleled flexibility for modifications, seamless solutions, and high load-bearing capacity, ensuring adaptability as your factory evolves. - Strength and Durability

50% stronger with our innovative concrete technology, providing unmatched durability and longevity for giga factory floors and foundations. - Accelerated Construction Timelines

30% faster installation and expedited project completion without compromising quality.

PrīmX Technology benefits

Jointless Jointless, saw-cut free floors - true flexibility, no limitations on racking placement.

Jointless Jointless, saw-cut free floors - true flexibility, no limitations on racking placement. 30% Faster construction No joints, saw cutting, rebar placement - shorter schedule, reduced costs.

30% Faster construction No joints, saw cutting, rebar placement - shorter schedule, reduced costs. Full responsibility Full warranty: materials, design, execution.

Full responsibility Full warranty: materials, design, execution. Perfect for AGV Jointless, saw-cut-free lifetime flat floors.

Perfect for AGV Jointless, saw-cut-free lifetime flat floors. Stay flat No joints, true flatness, no curling

Stay flat No joints, true flatness, no curling HygenicNo joints and no saw-cuts mean nowhere for dirt to accumulate. And nowhere for bacteria or viruses to hide.

HygenicNo joints and no saw-cuts mean nowhere for dirt to accumulate. And nowhere for bacteria or viruses to hide. Up to 70% less CO2 emissions Better materials, optimized design – reduced cross-section (less cement cons.). LEED points at no extra charge.

Up to 70% less CO2 emissions Better materials, optimized design – reduced cross-section (less cement cons.). LEED points at no extra charge. Low maintenance No joints to repair, no damage to forklifts, and no vibration-caused health problems for forklift operators.

Low maintenance No joints to repair, no damage to forklifts, and no vibration-caused health problems for forklift operators.

PrīmX Worldwide

We like to think big. Today our concrete solutions have been used in 4 continents and 29 countries across the globe.

• Latvia • Lithuania • Estonia • Sweden • Norway • Denmark • Finland • Israel • Germany • United Kingdom • Ireland • Poland • Netherlands • Belgium • Bulgaria • Hungary • Serbia • Kazakhstan • Romania • Portugal • Georgia • Azerbaijan • Saudi Arabia • United Arab Emirates • India • United States • Canada • Nigeria • South Africa • China

Contact Us