PrīmX Concrete Technology is a game-changer compared to traditional concrete, providing unmatched durability, efficiency, and flexibility — while improving safety and sustainability.

How do we create PrīmX?

“We believe in a systematic approach and continuous development to achieve perfection”

Unique PrīmX technology makes it possible to control concrete drying shrinkage – the biggest drawback of the world's most widely used construction material. The negative effects of concrete shrinkage lead to inefficient designs and material use, dramatically shortened service life of concrete structures, huge maintenance costs, and CO2 emissions.

PrīmX concrete is made with chemical compressive self-stress for stronger material, stiffer section, and improved hygral shrinkage control. Large dosages of the highest quality steel fiber reinforcement are used to restrain the chemical expansion of proprietary admixtures. Steel fibers accommodate flexural and shear reinforcing, and structures can be made completely without traditional rebars.

Result – much stronger, chemically tensioned, dimensionally stable material, ensuring several crucial design and performance benefits for concrete floors and other constructions, including higher load-bearing rating, reduced structure cross section, efficient jointless structures, watertight and gas-tight constructions, and more.

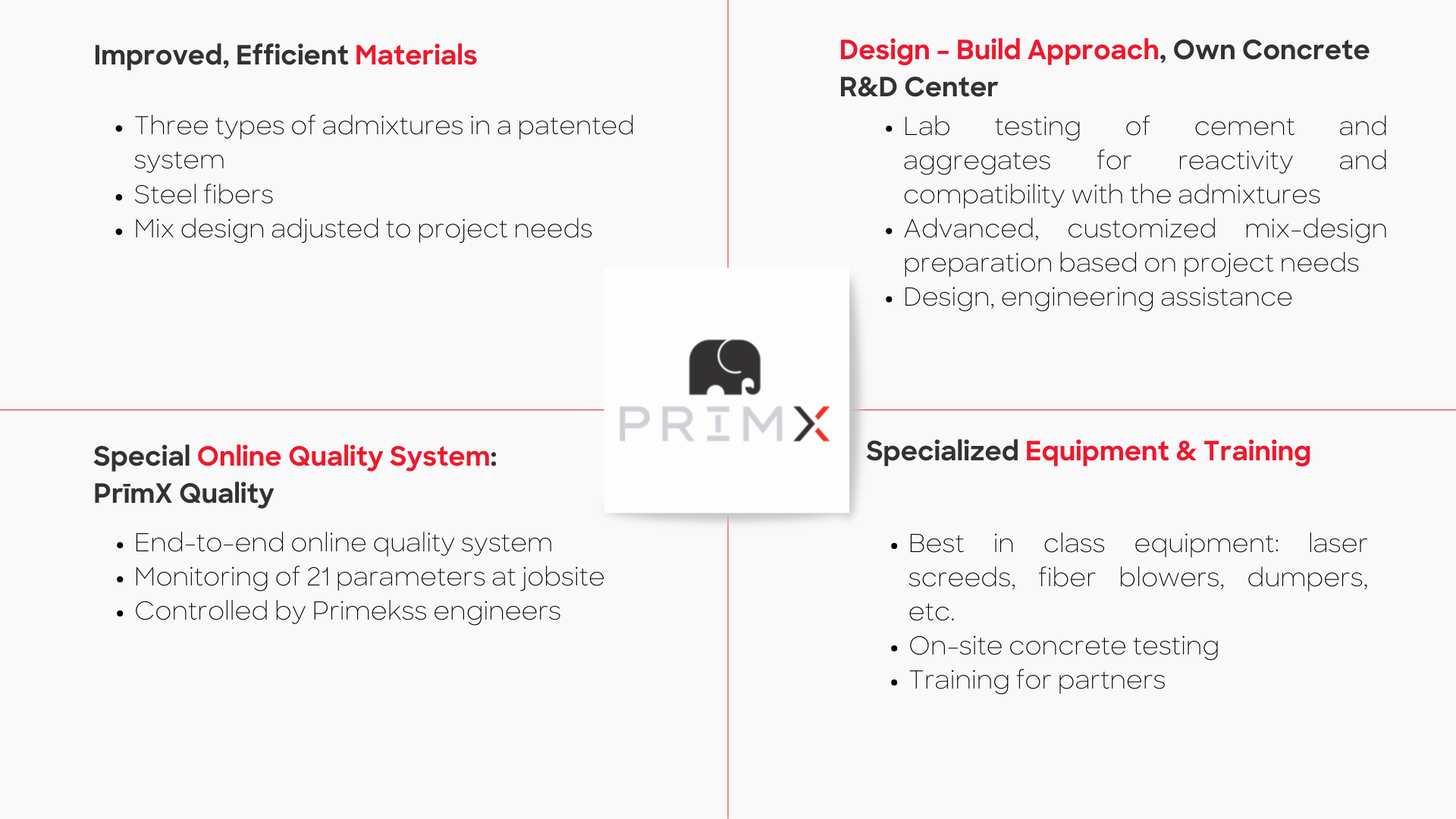

To guarantee predictable quality in PrīmX projects anywhere in the world, PrīmX is built as a technological system consisting of 4 building blocks enclosing key elements: improved materials, design – build capacity (independent structural and concrete engineering capacities and in-company concrete labs), proprietary, online quality control system – PrīmX Quality and specialized machinery.

These key elements allow us to deliver optimal product in every project: design, concrete mix and control the quality during the entire product delivery process.

More than 24 million square meters of PrīmX floors and pavements are in service in distribution centers, warehouses, and manufacturing facilities around the world.

Application

CONCRETE FLOORING

-

Automated Guided Vehicle (AGV) Floors

-

Autonomous Mobile Robot (AMR) Floors

-

Automated Storage and Retrieval System (ASRS) Floors

-

Manufacturing Floors

-

Heavy Duty Floors

-

Freezer Slabs

OUTDOOR PAVEMENTS

- Outdoor Pavements, ensuring high wear and overall impact resistance PrīmX outdoor concrete pavements. Best solutions for raw material storage outdoor pavements, pavements near loading ramps, etc., where heavy equipment is used, and high load-bearing capacity is essential

STRUCTURAL CONCRETE WORKS

- Raft foundations - PrīmX raft (mat) foundations are watertight, very fast to install; does not need extra waterproofing and are perfect for limited building space. In many cases, the best solution for multistory residential and public buildings

- Watertight concrete solutions in various structural concrete applications with PrīmX. PrīmX concrete doesn't need extra waterproofing

- Many structural, cast-in-situ PrīmX concrete applications where the properties of PrīmX concrete (non-shrinking, jointless, extra strong and stiff, water- and gas-tight solutions, high load-bearing) structures increase construction speed and worker safety and have all the benefits of sustainable construction

- PrīmX concrete in gas-tight solutions

PrīmX technology is delivered via our own resources (Baltics, Scandinavia, Germany, Israel) as concrete contractors or by qualified license partners worldwide who implement projects under strict Primekss quality control, ensured by Primekss Labs engineers (cement and aggregate testing, mix design adjustment, design, etc.) using only approved PrīmX materials.

As a specialized contractor, Primekss delivers design-build service – from the agreement to the ready floor handover.