The very well known in Central Europe Filigran system is efficient solution for construction using prefabricated structures. It takes the best aspects of both precast and cast in-situ methods to make construction easier and faster. Light, 50 mm (2 in) thick precast panels – called Filigran - are used as a base for further in-situ slab installation with both sections working in combination.

PrīmX - a High-Performance Steel-Fiber Reinforced Concrete (HPSFRC) technology has been installed in hundreds of millions of square feet of floors and structures worldwide, provides strong in tension and stiff steel fiber reinforced concrete with minimal steel bar reinforcement.

Combining both – PrīmX and Filigran - takes the system to the next level. The increased speed of installation, reduced rebar requirements, and benefit of the anti-shrinkage system make this combination a perfect solution for multi-story building construction.

Compared with alternatives

|

|

| Traditional system | PrīmX-Filigran system |

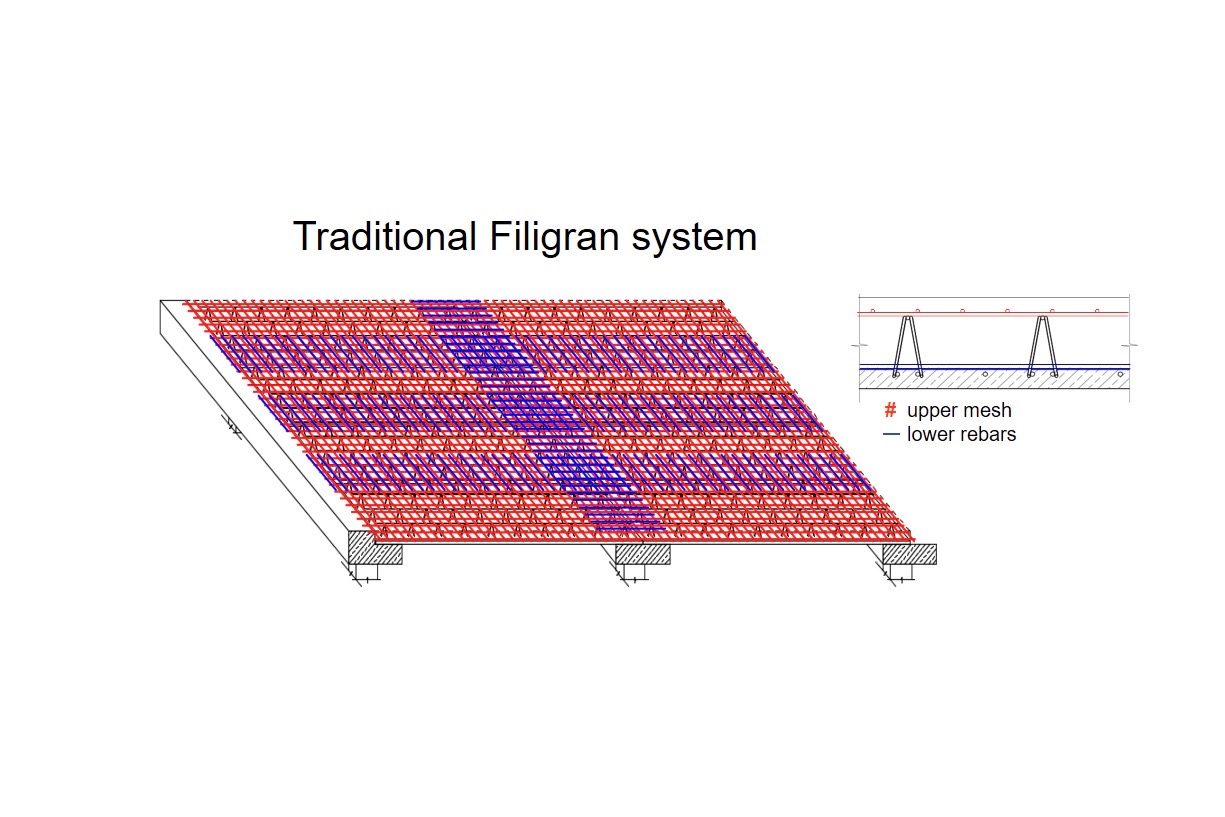

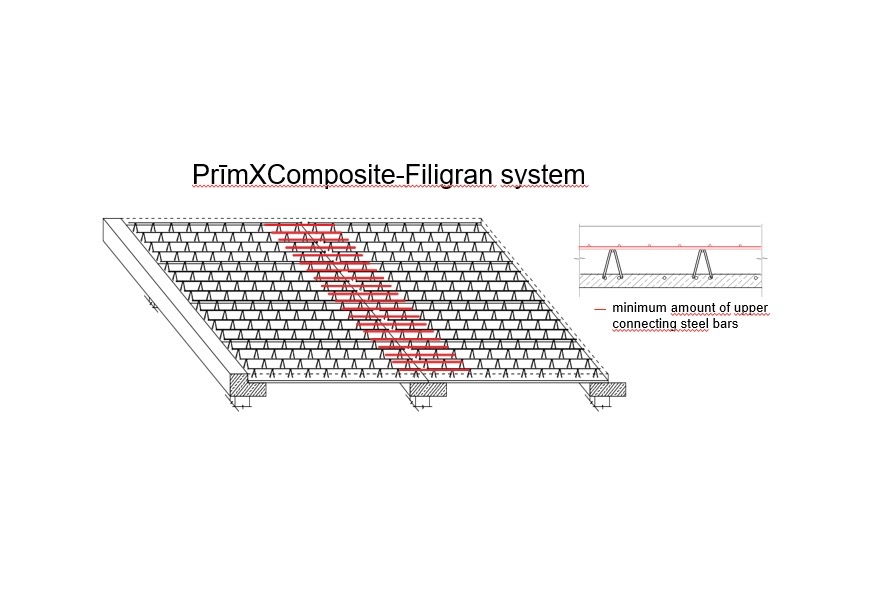

| In the traditional system, the in-situ slab must be reinforced with steel mesh and steel-bar tied panels. Mesh and steel bar installation is labour-intensive and dangerous for workers. (rebar unloading, use of rebar cutters, back strain, and possible stumbling on reinforcement mesh and girders). This method is slow and costly, affecting the entire construction process | In contrast, the PrīmX-Filigran system uses PrīmX concrete for the upper in-situ cast layer of the concrete. Due to steel fiber reinforcement, the need for steel mesh and steel bar installation is virtually eliminated. The steel fiber reinforcement is distributed evenly throughout, creating an extremely strong and stiff product. |

Due to anti-shrinkage system of PrīmX technology (expanding concrete), there is an opposite pre-camber deflection. Therefore, there is much less potential for cracking and deflection due to loading and the self-weight is significantly decreased.

Installing the PrīmXComposite-Filigran system results in 640 kg/100 sq. m. (1310 lbs/1000 sq. ft.) of steel bar reinforcement economy for a typical residential slab. The material properties of PrīmX (up to 50% stronger) allow the concrete slab thickness to be minimised and/or larger spans can be used. A typical slab can be reduced in thickness anywhere between 20 - 50 mm (1 – 2 in), providing impressive savings when used in multi-story buildings.

Find some completed projects in Case studies section.

Photo from building site – PrīmXComposite - Filigran system installation

Photo from building sites - traditional Filigran system installation

System benefits for involved parties: |

|

| For Contractor: | For Engineers/Architects: |

|

|

| For end user: | For Environment: |

|

|